If your nozzle is too far from the bed there is not enough filament extruded to properly fill the space between nozzle and bed.

Signs that your nozzle might be too far away from the bed: Make sure you’re not pressing down on your bed when levelling it.

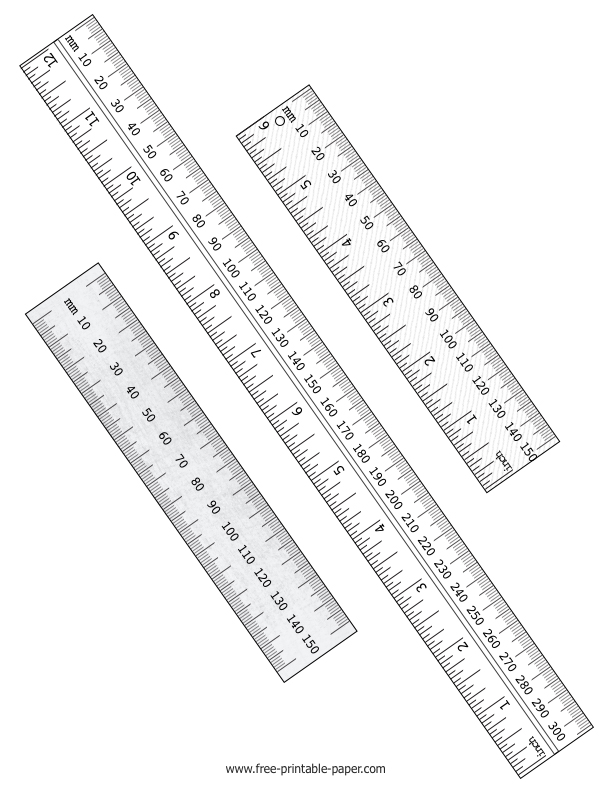

#Print to scale half mm lines manual

Squishing your first layer too much into the bed can lead to prints that are almost impossible to remove from the build plate when done.Īdjust nozzle to bed distance either by tightening the 3 or 4 levelling screws of your printer and using thicker paper stock for manual bed levelling or by adjusting your z-offset value when using a bed levelling sensor.If filament backs up in the HotEnd because it cannot get extruded due to the nozzle being too close to the bed, your extruder might even get jammed and start clicking.Excess filament might also get picked up by the nozzle and might drip back on your print later.Excess filament that gets squished to the sides and upwards might get torn off the bed on the next pass by the nozzle destroying adhesion and making the top of your first layer very rough to the touch.Excess filament is either squished upwards between individual printed lines or isn’t extruded at all creating additional pressure in the HotEnd.

If your nozzle is too close to the bed, there is not enough space between the nozzle and the bed to extrude the proper amount of filament.Finished prints are hard to remove from the print bed.Filament is getting torn off the bed when the next neighboring line is printed.(You can feel the roughness when touching it carefully even during the print). Excess filament is squished upwards at the edges of the current printing line creating a rough surface and wavy patterns.It might get so thin it turns transparent. Printed line is way thinner than desired.Signs that your nozzle might be too close to the bed: The heading beneath each picture can be clicked to expand. Otherwise, scroll down the sections to read up on different problems and find what compares to your prints. Once open, click on the problem you’re experiencing to jump to that section. On mobile: There is a Troubleshoot Menu (contents) at the top of the page for easy navigation. If you can’t see the issue from the content thumbnails, just take your time and scan through the guide to find the section you wish to read up on. There is an easy to use, expandable contents list along the left side when the article begins – just click on the problem you’re experiencing to jump to that section. To use the guide: On desktop: Hover over the thumbnails to zoom in on the image, if you’re not sure of the issue you’re looking for. Think this guide is helpful? Bookmark it so you’ve always got it to hand.

We’re unable to advise on all printers and material combinations though, so if you’re unsure it’s best to either check with your supplier or run your experiments on the filament. Please note: Our guidance is based on findings from extensive tests carried out with our own rigid.ink filament. Hopefully, this guide saves you hours of frustration – if you feel it’s useful to you please share it & tell others!

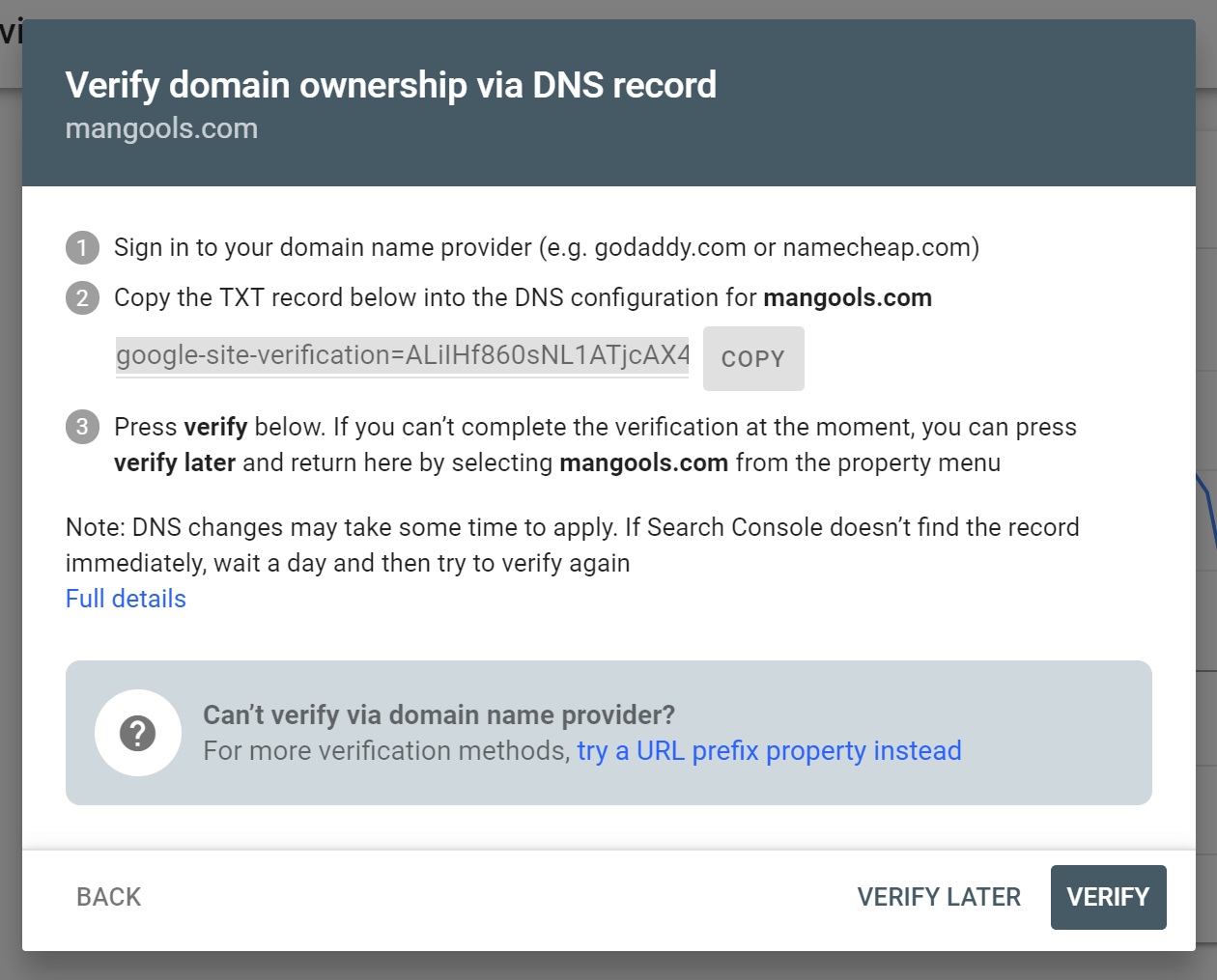

#Print to scale half mm lines software

This includes instructions for software settings and even best practices for specific prints and materials, where applicable.

0 kommentar(er)

0 kommentar(er)